FIRE POLY FPCC FIRE POLY FPCC |

CLEAR FIRE RETARDANT COATING for COMPOSITES ● FIBERGLASS ● PLASTIC ● PLASTIC PIPE ● PVC ● PLASTIC PANELS AND SHEATHING ● STYROFOAM ●POLYURETHANE FOAM ● POLYSTYRENE ● FOAM INSULATION ●POLYPROPYLENE ●EPS ● XPS ●PC ●EPS ●XPS ●HDPE ●POLYISOCYANURATE RIGID INSULATION BOARD

|

CLASSIFICATION FOR PLASTIC PIPE INTERNATIONAL MARITIME ORGANIZATION (MQ) RESOLUTION A 753 (18) ASTM F1173-95 FIRE RETARDANT COATING |

TESTING AGENCY SOUTHWEST RESEARCH INSTITUTE |

| TEST | MATERIAL TESTED | RESULTS |

| Fire Endurance and Hydrostatic Evaluation Based on International Maritime Organization Resolution (MQ) Resolution A.753(18); Appendix 2 and ASTM F1173-95 Section A5 Wet Condition Classification of Water Filled Plastic Pipe | Conley epoxy 20, 6-in. FLGXFLG Spool pipe coated with Flame Safe Chemical Corporation's Fire Poly FPCC | Passed |

| FIRE ENDURANCE | PASSED |

| Number of fire retardant coats | 1 |

| Rate per coat (ft2/gal) | 200 |

FIRE RETARDANT COATING for STYROFOAM ●POLYURETHANE FOAM ● POLYSTYRENE |

| TEST | MATERIAL TESTED | RESULTS |

| NFPA 701 | 3/4" Styrofoam painted with green latex paint and coated with Flame Safe's Fire Poly FPCC 3/4" Styrofoam (white) coated with Flame Safe's Fire Poly FPCC |

Passed

Passed |

| LOW VOC |

|

Fiberglass reinforced plastic panels Fiberglass reinforced plastic panels |

FIRE POLY FPCC |

TECHNICAL DATA Fire retardant for plastic type substrates such as Plastic Pipe and styrofoam, polystyrene, Polycarbonate HDPC, polypropylene, PVC, |

|---|

PRODUCT DESCRIPTION: Aqueous Based Resin

| PRODUCT ANALYSIS | ||||

|---|---|---|---|---|

Total Solids |

63% | PH | 2.5 - 2.8 |

|

Weight per gallon |

13.2 lbs | Flash point | Non-Flammable |

|

Specific gravity |

1.33 | Color | Milky white, dries clear |

|

Volatability |

Non-Volatile | Solvents | Water(Contains no petroleum or derivatives of petroleum) |

|

Anti-Fungus |

excellent Resistance | Bacterial | Good Resistance |

|

Linear shrinkage |

None | Moisture Absorption | Slight |

|

Corrosive |

Mildly | Non Toxic | None (when dry) |

|

Scrubability |

1000 cycles | Incompatiblilty | Strong oxidizers, alkalis or acids (materials to avoid)

|

|

Toxicity |

None, when dry | |||

| Volatile Organic Compound - VOC |

RECOMMENDED USE: Pressurized plastic pipe, fiberglass and plastic, composite piping systems, plastic conduits, styrofoam, polyurethane foam, styrene

FLAME SAFE FIRE POLY FPCC is a high intumescent coating that is specifically formulated as a fire retardant and smoke inhibitor for various plastic type substrates. It specially formulated for interior and exterior use and be overcoated with paint. When applied in an interior application and according to Flame Safe's specifications, it is a permanent and effective fire retardant for the life of the structure provided it is not removed by extraordinary means or exposed to extreme moisture conditions.

ENVIRONMENTAL REGULATION:

This product complies will U. S. Federal Regulations concerning the use of lead in paint and hydrocarbon emissions.

|

QUICK REFERENCE FOR APPLYING FIRE POLY FPCC |

|---|

| MATERIAL | APPLICATION |

COVERAGE RATE |

Plastic Pipe, PVC pipe, Composite pipe

Plastics Cabling Styrofoam, Polyurethane foam, polystyrene, EPS, XPS, HDPE, PC, PVC, PMMC and other plastic substrates |

Be sure surface is clean and dry before treating. Brush or roll coater Be sure to allow drying between each coat. |

1 coat @ 200 sq. ft. [18.58 square meters] per gallon [3.785 liters] - recommended 2 coats @ 400 sq ft [37.16 square meters] per gallon [3.785 liters] or 3 coats @ 600 [55.74 square meters ] sq ft per gallon [3.785 liters ]

For maximum efficacy Apply three (3) coats at 600 sq. ft. [55.74 sq. metes ] per gallon [3.785 liters] with the final coverage rate of 200 sq. ft. [18.58 sq.meters] per gallon [3.785 liters] |

EXTERIOR / INTERIOR All surfaces to be treated must be clean and dry. Fire Poly FPCC is water based, milky in it's liquid state. Dries Clear, becomes insoluble when dry. If over-coating is intended, Fire Poly FPCC is an excellent primer for use under latex paints, recommended. Avoid wasteful runs and dripping. It should be noted that unlike some products, materials treated with Fire Poly FPCC require no special cutting tools or special fasteners. Contact parts of any equipment should be stainless steel or plastic to prevent chemical reaction and breakdown. . |

.jpg) Clear Flame Retardant for fireproofing Plastic and Plastic Composites Clear Flame Retardant for fireproofing Plastic and Plastic Composites |

|---|

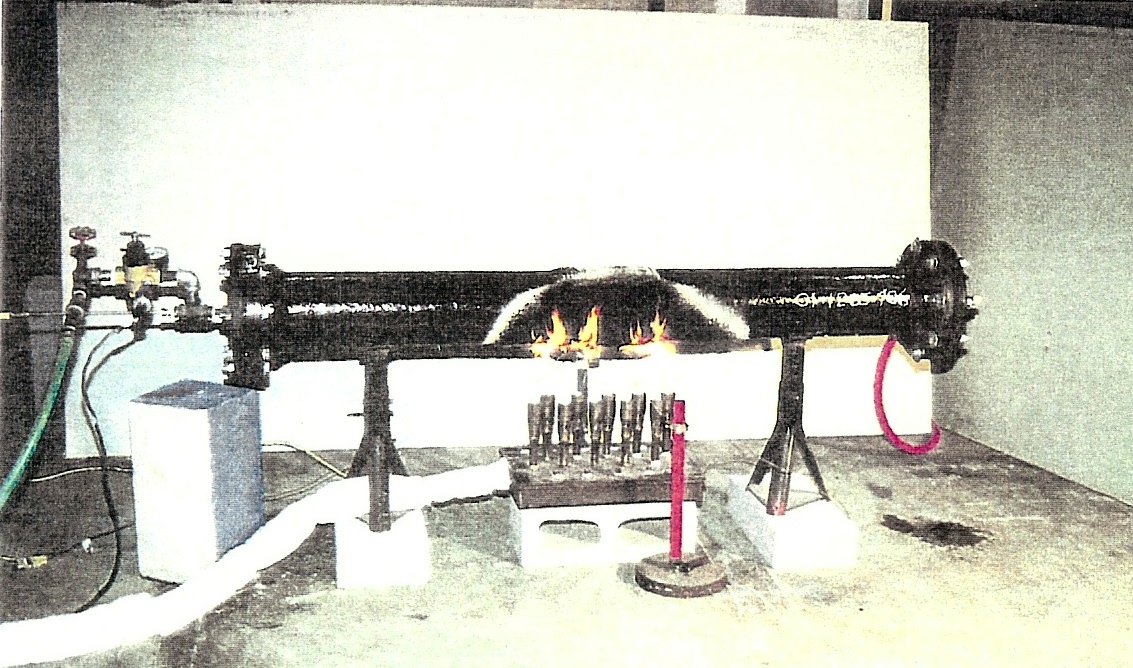

Internal fire endurance test for discontinuous filament wound fiberglass Tecnoplast testing Internal fire endurance test for discontinuous filament wound fiberglass Tecnoplast testing |

Fire Retardant for Fiberglass (FRP) plastic pipe test Southwest Research Institute Fire Retardant for Fiberglass (FRP) plastic pipe test Southwest Research Institute |

CAUTION:

Product must not freeze. It must not be thinned or diluted.

OVERSPRAY:

The overspray will not harm plants or animals. Spills can be flushed with water.

A rag wetted with bleach and water mix will clean up spotting.

CLEAN UP PROCEDURE:

Airless Equipment.

1. Run clear water through the system until coating is flushed out. When minor sudsing on surface stops, the system is flushed.

2. Run bleach and water mix (1 part to 4 parts) through system as solvent for cleaning any residue.

3. Repeat Step 1 if any foaming occurs in Step 2.

4. Lubricate system as specified by equipment manufacturer to combat rusting.

If two or more applications are planned in the same day, the sprayer can be kept

clean by running water through the system between applications.

Brushes/Rollers.

1. Clean immediately after use.

2. Wash thoroughly with bleach and water mix (1 part to 4 parts).

SAFETY FIRST

Use approved safety devices (ropes, belts, ridge hooks, ladder, etc.) When working on steep or high areas. Take EXTREME CARE not to step on wet treated area. Surface may be slick until dry.

It is good practice to wear respirator or mask and protect hands with rubber gloves when spraying any coating or chemical. When engineered air control is not feasible, use properly maintained and properly fitted NIOSH approved respirator for solvent vapors. A dusk mask does not provide protection against vapors.

If eye contact occurs, flood with water for fifteen (15) minutes and call a physician. KEEP OUT OF REACH OF CHILDREN. DO NOT TAKE INTERNALLY.

| CALL FOR OUR DAILY DISCOUNT ! ! |

| Call for pricing and ordering 1-800-333-9197 |

Expanded polystyrene insulation

Expanded polystyrene insulation